- enquiry@labindia.com

- 022 - 2598 6000

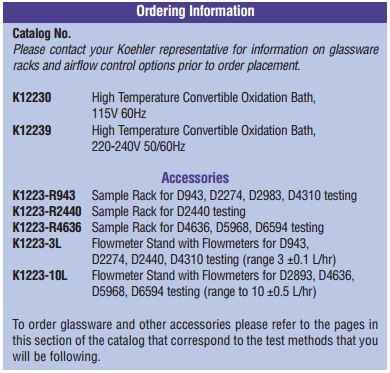

Home / Petro Division / Koehler Instruments / Lubricating Oils / High Temperature Convertible Oxidation Bath

High Temperature Convertible Oxidation Bath

Copyright © 2020 Labindia-Instruments | SEO and Web Design by Product Search India