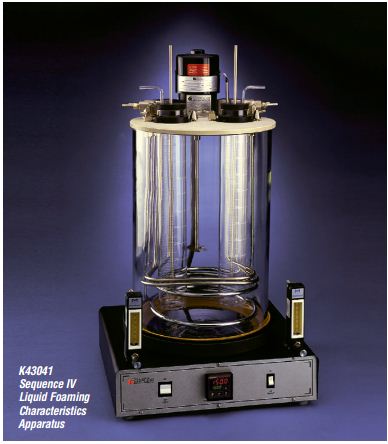

Sequence IV Liquid Foaming Characteristics Apparatus

Test Method

Foaming of lubricating oils in applications involving turbulence, high speed

gearing or high volume pumping can cause inadequate lubrication,

cavitation, overflow and premature oxidation. The sample is blown with a

controlled volume of air at different specified temperatures, including a

newer high temperature test at 150°C. The resultant foam is measured at

the end of each aeration period and at different intervals afterwards. In the

high temperature test, the amount of time required for the foam to collapse

to "0" after the aeration period is also measured.

Foaming Characteristics Test Baths

. Dual-twin models for standard foaming characteristics tests

. High temperature liquid bath for 'Sequence IV' tests

. Automatic time sequence models for both tests

. Custom configurations for specialized applications

Dual Twin Foaming Characteristics Test Apparatus

Performs two

tests at 75°F (24°C) and two tests at 200°F (93.5°C). Consists of two 12x18"

(30.5x45.7cm) constant temperature baths with 1000mL test cylinders, certified

diffusers, air delivery tubes, and flowmeters (94mL/min.) for each sample.

Baths are equipped with microprocessor temperature controls, copper

immersion heaters and 1/20hp circulation stirrers to maintain temperature

uniformity of ±1°F (±0.5°C). Microprocessor PID control provides quick

temperature stabilization without overshoot and the bath is protected by an

over temperature control circuit that interrupts power should bath temperature

exceed a programmed cut-off point. Dual LED displays provide actual and

setpoint temperature values in °C/°F format. Test cylinders are held securely in

place by quick-locking cams in the bath cover assembly. A separate stainless

steel support rack is provided to hold the test cylinders after removal from the

bath. Cold bath (24°C) has built-in coils for circulating exit air from the high

temperature test cylinders prior to passing to a volume meter, and a separate

coil for circulating cooling water or refrigerant when the ambient temperature

exceeds the test temperature. Supplied with rubber stoppers and glass air

outlet tubes for each cylinder. Bath controls are enclosed in a finished steel

base with chemical resistant polyurethane enamel finish. Communications

software as seen on page 110 (RS232, etc.), ramp-to-set and other

enhanced features are available as extra cost options. Contact your Koehler

representative for information.

FTM 791-3213 Aircraft Lubricants Test

Employs more severe conditions

-smaller sample, increased air flow, longer aeration period-to test the

foaming characteristics of aircraft-turbine lubricants. All models are available

on special order for FTM 791-3213 testing. Please call or write for specifications

and ordering information.

Specifications

Conforms to the specifications of : ASTM D892; IP 146; DIN 51566;

FTM 791-3211, 791-3213*; NF T60-129

Temperature Control:

Digital Setpoint and Displays °C/°F

switchable ,

Built-in Over temperature Cut-off

Protection

Included Accessories

Test Cylinders, 1000mL (4)

Diffuser Stones, calibrated and

certified (4)

Air Delivery Tube Assemblies (4)

Air Outlet Tubes (4)

Rubber Stoppers (4)

Bath Jars (2)

Support Rack (1)

Acrylic Safety Shield, 18"

High Temperature 'Sequence IV' Liquid Foam Test Bath For two tests

at 150°C with a flow rate of 200mL/min. in accordance with ASTM D6082

specifications. Consists of a constant temperature bath with 1000mL test

cylinders, certified diffusers, air delivery tubes and flow-meters.

Microprocessor PID control provides quick temperature stabilization without

overshoot and the bath is protected by an over temperature control circuit that

interrupts power should bath temperature exceed a programmed cut-off point.

Dual LED displays provide actual and setpoint temperature values in °C/°F

format. Quick response copper immersion heaters provide efficient high

temperature operation, and a stirrer unit provides complete circulation for

temperature uniformity of better than ±1°F (±0.5°C). Locking cams hold the

test cylinders in a vertical position, and a separate rack is provided to hold the

cylinders after removal from the bath. For operator safety, an acrylic heat shield

surrounds the Borosilicate Glass bath jar. Communications software (RS232,

etc.), ramp-to-set and other enhanced features are available as extra cost

options. Contact your Koehler representative for information.

Specifications

Conforms to the specifications of : ASTM D6082

Temperature Control:

Digital Setpoint and Displays °C/°F switchable ,

Built-in Over temperature Cut-off Protection

Included Accessories

Test Cylinders, 1000mL (2)

Diffuser Stones, calibrated and certified (2)

Air Delivery Tube Assemblies (2)

Air Outlet Tube (2)

Bath Jar (1)

Support Rack (1)

Rubber Stoppers (2)

Acrylic Safety Shield, 18"

REQUEST A QUOTE